Founded in 2018, Delft-based startup Arceon has been building its reputation in the space industry and growing its range of innovative materials. Since graduating from the European Space Agency’s business incubation programme (ESA BIC Noordwijk) in 2023, the startup’s trajectory has seen the team going from strength to strength. There have been multiple ESA contracts, exciting collaborations, successful funding rounds, material samples launched into low-Earth orbit and an expansion of its catalogue of ceramic matrix composites. We spoke to co-founder Rahul Shirke about developments, challenges and what’s next for Arceon.

Arceon’s founders Rahul Shirke (CEO) and Rahul Sharma (COO) started their journey at ESA BIC Noordwijk in 2021. It was during incubation that they explored the technicalities and business opportunities of their durable, lightweight material Carbeon. Made with carbon fibre and silicon carbide matrix composite, Carbeon is resistant to extreme heat, stress and corrosion – perfect for innovative applications in space and on Earth.

Before graduating from ESA BIC Noordwijk, Arceon had already closed its first funding round and delivered a nozzle prototype. Since then and with the added support of co-founder Bernhard Heidenreich (CTO), the team has secured several ESA contracts, while in parallel expanding further into the defence sector. With their novel material, the founders want to bridge the gap between research and industry.

Arceon was incubated at ESA BIC Noordwijk between 2021 and 2023. What are the main things you worked on during that period?

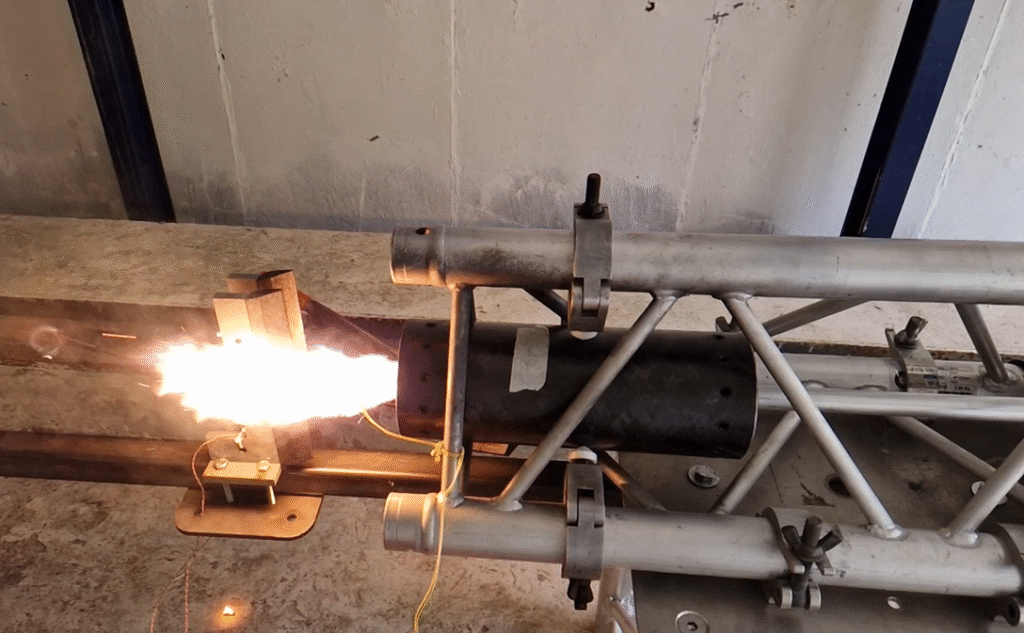

During the ESA BIC programme, we were focused on creating a component that could be used as a nozzle for rocket engines. At that time, we wanted to prove that we could manufacture these complex shapes. We also filed for a patent during that phase, which we plan to use for a couple of future projects.

We have secured some ESA projects on the same component. We have also raised two rounds of investment: in 2023, we raised our first investment round through UNIIQ; and in 2024, we raised another round of investment through Tenzing Alpha, our current investor.

Are there any other major learnings you took from the incubation?

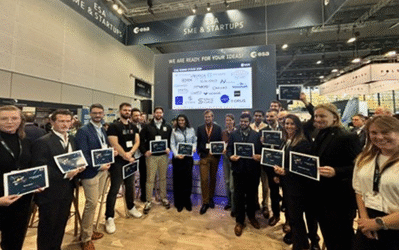

We learned a lot about the space sector because of the network that ESA BIC facilitates. At many events, like the Space Tech Expo in Bremen, we met companies through which we get to learn a lot more about the sector itself, how it operates, what the cost is of changing something, and how many companies are willing to change their existing design to a new one. These are the market validations we got through ESA BIC. There were also regular opportunities to pitch our company – such as at Space Expo and at the NL Space Campus Network & Drinks in Noordwijk. This is also where we made new connections through the Netherlands Space Office (NSO), which in the end actually got us our first ESA project. The pitch events are a fantastic way to expand your reach in the space sector.

The pitching opportunities available through ESA BIC are a fantastic way to expand your reach in the space sector

rahul shirke, arceoN CEO

What advice did you get during incubation that really helped your company?

It was about selecting the component. We don’t sell the raw composite material, but the finished product, so for us it’s very important to not only analyse the sector where we are going to enter, but the winning product as well.

Throughout our ESA BIC incubation, we had business support meetings with Gerard Hegemans, who was the CEO of SBIC at the time. His advice helped us narrow down where, which sector – should we go with space or defence first – and with which component. That gave us the initial push to focus further.

What were your key moments during incubation or since graduating?

In 2023, we increased our workforce. Yestin van Haaren joined our team as a senior project engineer and Girish Malage started as a design engineer. They have been very valuable additions to our team. In 2024, we did a lot of projects for smaller companies in the space domain. But we realised that smaller companies either have funding bottlenecks, the projects don’t go ahead or testing takes a lot of time.

How did this help you to refocus your approach?

This year, we consciously decided that we would focus on ESA projects because they are funded by ESA, but also, they are with an end customer. ESA has been very proactive with the tenders and the way they want to proceed. There have been programmes opening which were relevant for us and we managed to score three projects:

- ESA General Support Technology Programme (GSTP, de-risk framework) with TNO;

- ESA Technologies for High-Thrust Re-Usable Space Transportation (THRUST!) with The Exploration Company; and

- ESA Future Innovation Research in Space Transportation (FIRST!, propulsion category) with Ecaps.

We are also active with defence primes from the EU, UK and USA.

What are these projects you are working on now?

Our project with ESA BIC Bavaria alumnus The Exploration Company for the ESA THRUST! initiative, where we are part of the consortium, focuses on deploying lightweight and high temperature resistant nozzle extension. For the ESA FIRST! campaign, we are co-developing attitude control thrusters with Ecaps, a Swedish chemical propulsion company. For this, we are the project lead having recently received a best proposal award from ESA. That was a special moment because we were not expecting it, but ESA recognised that we had a very strong proposal but also end customer and good base to it. That was a massive achievement for our team. Fortunately – or unfortunately – the work starts after that, so we are focused on delivering on the small fame we got there. Basically, many companies got to know about us and that helps with forming consortiums for upcoming projects as well.

Arceon’s materials are undergoing in-orbit tests. What is the focus of this particular project?

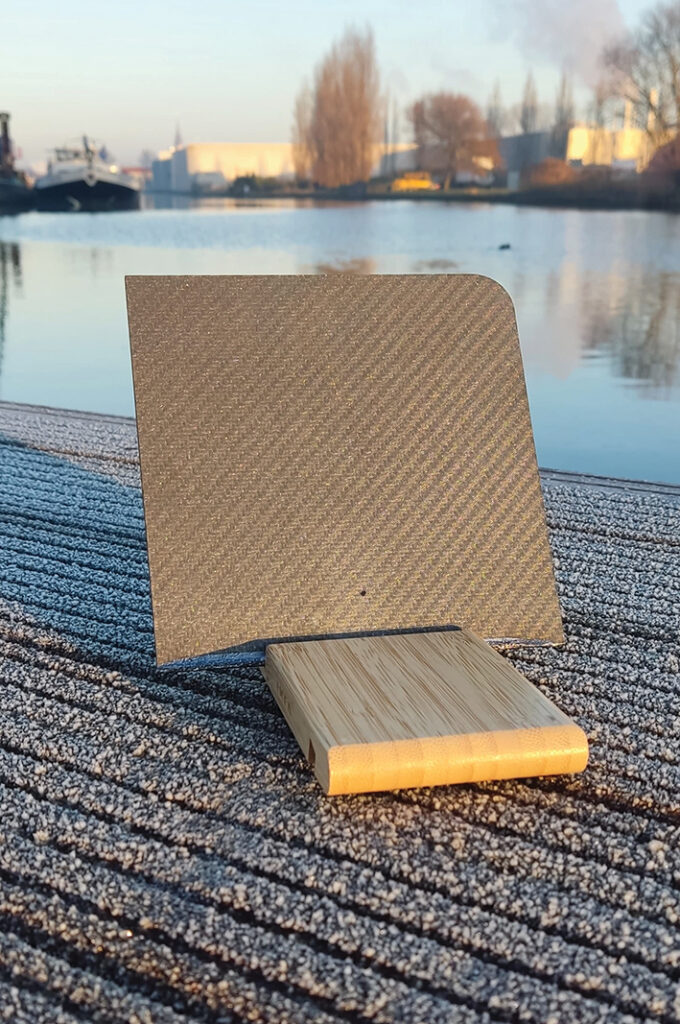

Our payload was launched to low-Earth orbit in November 2024 and then was installed on the outside of the International Space Station by the end of the year. It is part of Euro Material Ageing project, in which ESA wants to observe the ageing behaviour of new materials in space. ESA did some initial ground tests and our material performed very well. But on Earth, you can only simulate one condition at a time; you cannot put two or three conditions together. In space, there is UV radiation, space debris and so on, so that’s why they want to see what happens to the material when everything comes together. We have four of our material variants up there for at least a year. This is actually relevant for the first ESA project we scored, for the ESA GSTP! de-risk framework. For that, we’re working on optical telescope structures which will function in low Earth orbit. The goal is basically to study the ageing of the material and then complement that with the product.

What other sectors do you have your sights on?

We have also been working with the defence sector since 2021. There, we are only focusing on the big players, within Europe but also in the US. Now, we are part of UK Ministry of Defence’s Hypersonic Technologies & Capability Development Framework as one of the links in that whole supply chain.

What are challenges you are currently facing?

With respect to business challenges, it still takes time to explain the advantages of using components from composite materials to the customers, so we would like to speed up this process. That’s why we are trying to complete further tests, which help prove the reliability of our components for the customer.

With respect to technical aspects, each product is different, so we do face some technical challenges. To start with, we use a deep tech manufacturing method for the ceramic matrix composites, so it’s not very easy, but there are solutions which we are implementing. We are also planning to move to a bigger facility because we want to purchase some bigger equipment. So, on the technical side it’s more about upscaling and then moving fast.

One challenge for Arceon during incubation was that your customers’ standard material of choice was mostly super alloys or metal alloys. Has this changed since then?

We have noticed a slight shift in attitude toward using ceramic composite materials. Our composite is still a new material, so it does take some effort for us to convince the customer that it’s something that will work, save them money or give them other benefits. That’s still a challenge. Interest in ceramic composites is increasing, though. More big contracts are getting signed across the industry. For example, Firefly, a US-based space company, recently got a project from Air Force Research Lab in the US for developing components similar to ours. It’s funny, the US is a bit late to the game with these kinds of components. We are quite ahead in the development. Europe can be proud that they have these things already sorted while the US is just starting. So, slowly, others are starting to realise the importance of ceramic composite materials.

What’s next for Arceon?

Our focus for this year is to complete product development for the nozzle and deploy it commercially by next year. For the near future, we are going to be focusing on just a few projects because we are limited with the number of people we have. We are focused on completing those projects thoroughly, with all sorts of testing to ensure a robust quality and go for commercialisation. In 2026, we target signing commercial contracts for annual orders.

How about longer-term ambitions?

In the longer term, we would like to enter cross sectors. For this, we are looking at a different shape of our composite material – such as plates, tubes, cones and cylinders. Currently, we are selling these plates to any cross-sector request we get. The requesting company does tests, looks at the material, whether it works or not.

For example, Saint-Gobain is currently testing our material for wear resistance. A metal powder production company is also currently evaluating whether it works for them. Other applications being investigated include battery casings for electric aviation and metal heat treatment.

We don’t want to go into everything at once, so right now, plates are the easiest way for us to test the feasibility of the material. So, that’s what we offer to these customers.

Do you have any learned lessons or advice to share with other entrepreneurs?

Risk is something that you should be willing to take. Sometimes, we have to take a bold step to move forward and just not be afraid to do that. This has not changed much since my first ESA BIC interview, actually. We target some ambitious goals, we aim high. If we’re going for ten out of ten, we will reach around eight or nine and then work our way towards that ten. I’m an optimistic person, a hopeful person, so I’m always convinced that we can do it.

Want to be part of Arceon’s journey? The company is in the final stages of completing a funding round and any interested co-investors should reach out to learn more.

ABOUT: Arceon empowers revolutionary technology advances by developing materials with unique properties, such as extreme heat resistance, superior durability and reduced corrosion levels. Since graduating from ESA BIC Noordwijk in September 2023, the company has been busy developing various projects, including rocket nozzles, high-precision telescope tubes and thermal protection systems. The founders seek to advance humanity by empowering radical innovations with materials designed for extremes and look forward to further market opportunities. arceon.nl