Wren Aerospace is taking high-altitude pseudo-satellites (HAPS) into the stratosphere. Currently participating in the Dutch business incubator of the European Space Agency (ESA BIC Noordwijk), the team is developing its unmanned aircraft to offer superior network connectivity and sensing capabilities. Composite materials and hydrogen technologies developed for space missions have been leveraged in the design, which delivers structural integrity, aerodynamic efficiency and stability in harsh stratospheric conditions. The autonomous platform will be payload agnostic and suitable for situations requiring telecommunications, surveillance and reconnaissance. We caught up with founder Julius Jördens to find out how Wren closes the gap between airborne and orbital assets.

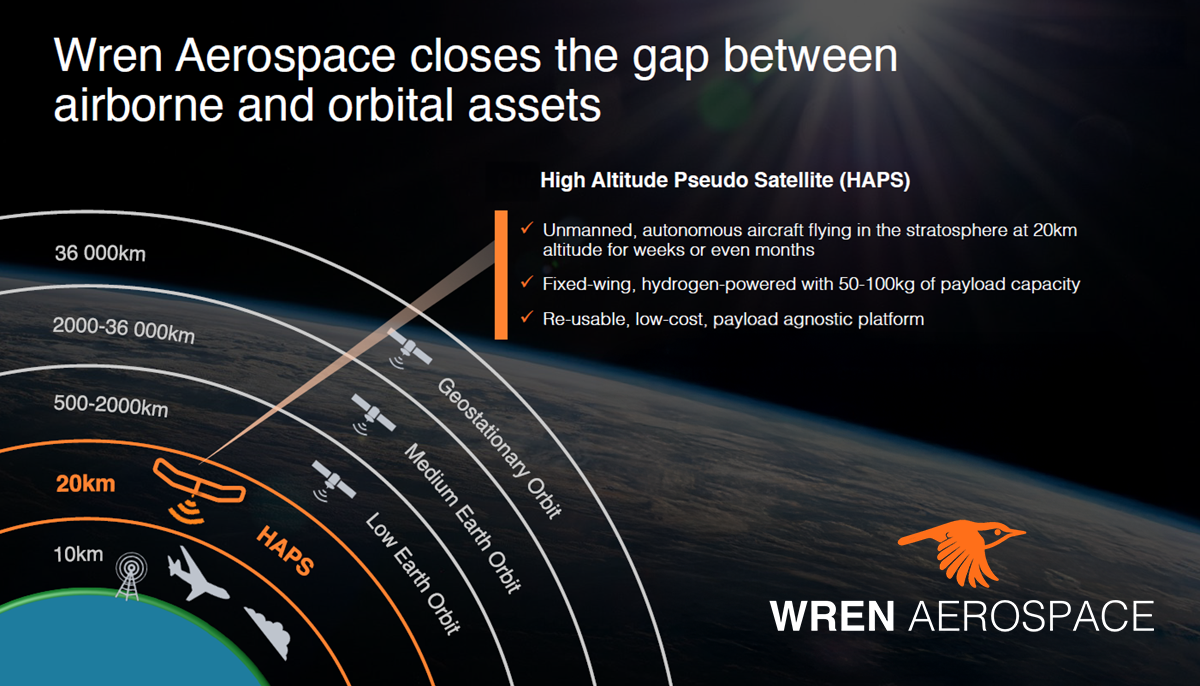

Before we jump in, let’s start with asking a question: Where does space actually begin? One definition (widely, yet not universally accepted) states objects need to have passed an imaginary boundary known as the Kármán line to be in outer space, which is about 100 km above sea level. Below that, there is the mesosphere and below that again is the stratosphere (max. altitude 50 km). It is this important atmospheric layer that the Wren Flyer unmanned aircraft – high-altitude pseudo-satellite (HAPS) (see also another definition) – has as its destination, operating at up to 20 km above the Earth. HAPS aircraft can fly for weeks or months and combine the advantages of satellites with those of unmanned aerial vehicles (UAVs). By being so much closer to the Earth’s surface than satellites in orbit, this comes with many advantages while also retaining the advantages of ground-based aircraft. It is beneficial for changing payloads between missions, offering more flexibility than single-launch orbital satellites.

Wren Aerospace was established in early 2025 in the Netherlands by co-founders Julius Jördens (CEO) and Firas Arab (CCO) – and, currently, has two part-time members working in parallel from New Zealand: Max Garber (lead engineer) and Michael Daly (soon-to-be co-founder and CTO). Its inaugural product – a fixed-wing HAPS platform – can be seen as providing a service complementary to satellites, such as acting as communications relay and a temporary network during disaster recovery and acting as a cell-tower in the sky for local demand coverage. The advantages of HAPS vehicles sound promising, though the reliability of the current fragile and highly-sensitive aircraft concepts is low. This is where the innovative design of Wren comes in by offering improved structural efficiency, reduced weight and increased stability during flight. Since joining ESA BIC Noordwijk in June 2025, the startup has been progressing the development of its HAPS technology. Read on as Julius explains how applying space technology strengthens Wren Aerospace’s solution.

How do you describe the focus of your startup?

We are unlocking the power of the stratosphere – the layer of the atmosphere that is currently barely used at all. And that’s because nobody’s got a reliable and economically viable platform to operate at that altitude yet. That’s why when we say we are “unlocking” – it’s really about still being the first to have a viable platform. There have been plenty of concepts and prototypes with some very successful test flights, but no airships or fixed-wing vehicles have taken off commercially yet.

The focus is on finding a platform and a commercial model that allows us to leverage the benefits of the stratosphere; the benefits being that you are really closing the gap between airborne and orbital assets. So, you have the advantages of satellites, with big coverage area, but you also have the advantages of airplanes and drones, which is that you can land the aircraft and change the payload. So it’s a very interesting proposition that, currently, nobody is able to turn into reality.

What’s the space link in your innovation?

We are using three aspects of space technology in our aircraft. The stratosphere is somewhat similar to the space environment, with its very large temperature gradients from day to night and of course radiation (which can impact the aircraft). So, firstly we are opting for a composite structure akin to those developed for space missions. Next, is our hydrogen propulsion system, which needs to operate at minus 60 °C, which is something very different to using hydrogen on Earth. Our long-term vision is to create a regenerative source, kind of like a battery with solar cells that produces and stores hydrogen during the day and, at the night, this hydrogen is then converted to electricity for power. Finally, the third link is that we use a novel control method inspired by space re-entry vehicles to control the aircraft in the thin air of the stratosphere.

Get financial support (€60K funding) to help launch your space business >>

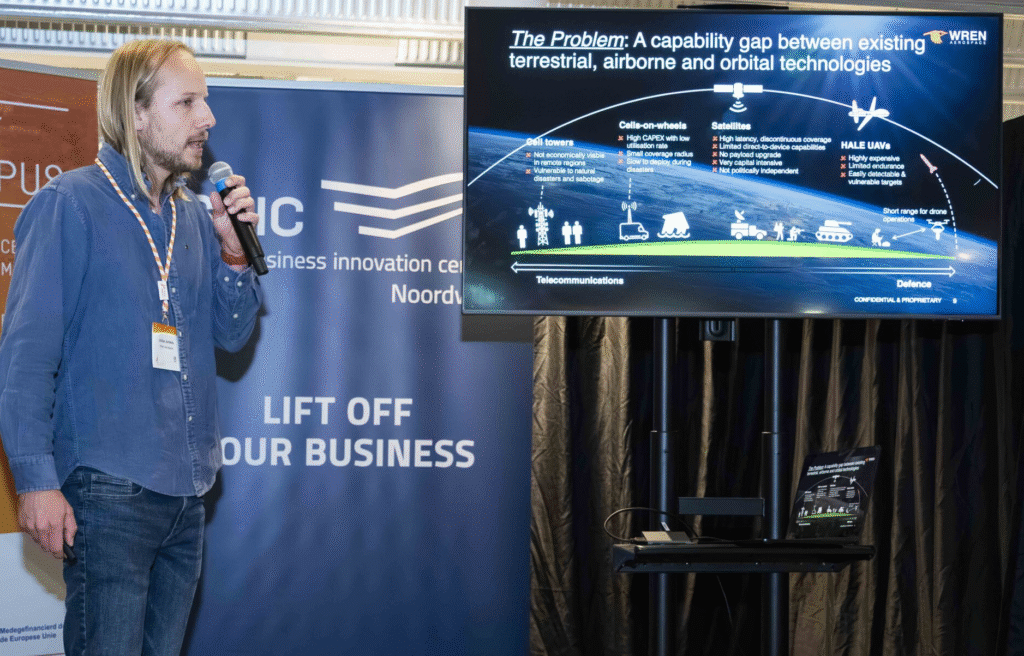

What problem is your solution addressing?

There is a capability gap between existing terrestrial, airborne and orbital technologies. For the HAPS market, there are different concepts – balloons and airships have proven themselves for certain applications, but can be blown off target by stratospheric winds and are thus not ideal when one needs to operate in a given location with absolute reliability. We believe the most interesting developments will happen in the fixed-wing aircraft segment. So far though, many existing concepts are highly sensitive to atmospheric conditions and too fragile; even mild turbulence can destabilise them. To reach stratospheric altitude, they typically require exceptionally calm conditions – i.e. wind speeds below about five knots (around 9 km/h) from ground level to the upper atmosphere. Stronger winds at any altitude can make ascent very difficult or impossible. Our focus is to have an aircraft that’s still equally efficient, but much more durable and stable in its design. All the research we’ve done suggests that the platform is really the challenge that nobody has been able to crack yet. Our platform will have an airframe that is sufficiently strong and stable while still achieving the efficiency to fly so high and for so long.

How do you get your product to fly in the stratosphere?

Getting the HAPS platform into position will be a challenge, as we’ll need to fly through commercial airline paths. For our type of aircraft, the regulations don’t exist. The airspace above 18 km doesn’t fall under civil airspace, so it’s sort of this new zone that is not covered yet. Climbing to that altitude falls under the current regulations but then management of the higher airspace is still something that’s in the definition phase and bodies, such as EASA (European Union Aviation Safety Authority), are expected to issue guidelines within a few years. We’re also hoping that there will be mechanisms put in place to make climbing to that stratospheric altitude easier. For example, certain launching corridors to allow these slower flying aircraft to cross the commercial jet paths. For now, we have to be compliant with either civilian or defence safety standards. And that will be a major challenge, of course. Designing something is one thing, but then proving that it’s safe enough to operate within civil airspace – especially because it’s an unmanned vehicle – will be a priority.

What is your background?

I studied aerospace engineering at TU Delft and my final bachelor thesis was about building an extremely lightweight, electrically-powered aircraft, with the opportunity to actually build an unpowered glider version. So it was essentially like an educational research project where we as students learned to make composite parts and to build this lightweight structure. Afterwards, we wanted to continue as a startup to build a one-seater sports aircraft but it didn’t have a market. From that though, we realised the basic layout actually had a lot of benefits for the HAPS because of our focus on reducing the aircraft weight and so we switched focus and built a 5-m wingspan prototype and flew it indoors successfully. We had verified the basic stability of the aircraft but we didn’t figure out the control.

This stayed as a hobby project for a while, alongside my day job, until last year when we put much more emphasis on improving the design. We came up with a novel control mechanism and made changes to house the payload. And, importantly, this was when we made a shift towards our hydrogen propulsion system instead of pure solar and battery. We’ve come up with this novel design, which is really inspired by the failures of previous fixed-wing aircraft. So we really tried to think about what’s the most durable, lightweight structures that we can make fly safely. And that’s our basic design now.

What inspired you to establish Wren Aerospace?

Back in 2020, I took initial steps with my first startup but decided it wasn’t the right time – mostly due to lack of funding and the COVID pandemic didn’t help either. So, I got a job as a consultant working with startups for 4 years. Being in that environment, I was really inspired to become a founder myself and I learned a lot about the startup ecosystem.

It made me realise that this HAPS idea was actually a very interesting topic and that if we put our heads to it, we can manage to make real progress. So, after leaving my last job, I decided to commit full time with a new company, which is when Wren Aerospace was born.

How did the founding team get together?

Gathering the team happened organically. Max and I go back a long way – from our TU Delft days when we were in the same student team. After studying, he moved to New Zealand for a new job. I knew he was still keen on this project and so we re-established contact last year and he agreed to come on board. In September 2024, he started building our first prototype and doing all the tech development in New Zealand (alongside his day job). He also brought on board another Kiwi contact, Michael Daly, who has the same passion for engineering as the rest of us. And I met Firas last year – we got on very well and his knowledge of the adjacent satellite communications industry, as well as his strategic and business development expertise, was impressive. He was interested to take on the challenge of building a company in this field and made a quick decision to get involved. So, we’ve never actually gone out looking for people, it has just happened naturally. I hope we’ll be in that position at some point as we expand the team, once we have funding.

How did you find out about the ESA BIC programme?

It was already on my radar for quite some time and also during my last job, of course, when I interacted with many tech startups. When we founded Wren, we didn’t have any funding yet for tech development and we didn’t have an office. And so ESA BIC looked like a good place to give us those really essential things in the beginning. We applied in spring 2025 and were happy to be accepted. It really helps to have a structure, be part of the ecosystem and to have the community here. It’s been really valuable as a startup.

What is your focus during incubation?

Even though we have a first battery-powered, 3D-printed prototype – from which we’ve already learned a lot during flight testing – it’s nowhere near as complex as what we’re aiming to have by the end of the programme. Our initial focus during incubation is really to validate the design in terms of efficiency and stability. We are currently doing the first flight tests outdoors investigating the aerodynamic properties and gathering data – turns, climbs, descents – and testing our new control mechanism that we’ve developed. Parallel to that, we’re already developing our bigger aircraft and our hydrogen propulsion system, which will enable operations in high latitudes where solar HAPS cannot reach – with more power available for greater airspeed and payload capacity.

By the end of the programme, we aim for an MVP (minimum viable product) that can carry 8 kg of payload with 2–4 days endurance and a range of over 13,000 km. Once we’ve collected enough data, then the focus will be much more on fundraising and also developing our more complex aircraft with a liquid hydrogen storage system, which will enable significantly longer operation in the stratosphere. We’ll be getting technical support for this, along with help to model the simulations of our aircraft. One big challenge is actually that the air is so thin that traditional aerodynamic control surfaces don’t have as much authority, and so we’ve developed something that works without, and we’re hoping it works much better in the thin atmosphere.

Are there specific challenges that you are experiencing?

Well, the cross the world co-working with half the team in New Zealand brings its own challenges. We only have like 2 hours in the morning when our time zones overlap, which is really late evening for them, and they’re tired from their days of work and we’re just starting the day. Also, the fact that we don’t yet have everyone on board full time has been slowing us down a bit. So we’re really looking forward to getting everybody full time right now and this will help us gather momentum. Then, of course, getting funding is going to be the next really big challenge in order to scale up the team and the tech development. When we are in a good position after having completed extensive testing, we’ll be engaging further with investors. With hard data showing our prototype is much more efficient with its lighter and stronger structure and therefore it’s much better suited than anything else on the market right now, we hope to convince even the skeptics.

Did you select an initial application area for your product?

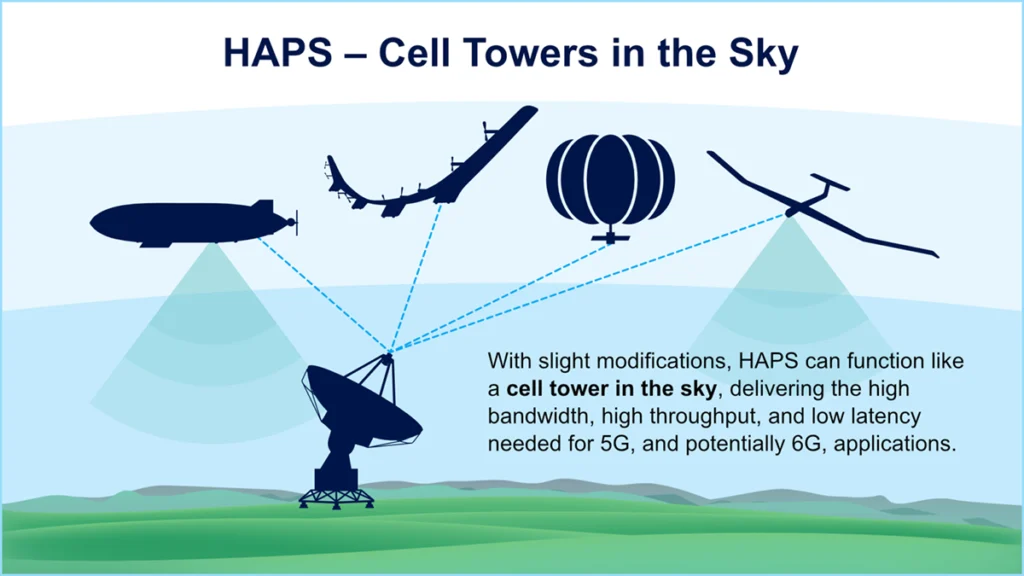

We’re offering a payload-agnostic platform that can be used for multiple challenges, but what we are focusing on is to help mobile network operators to fill gaps. This could be either due to disasters; if there’s an earthquake or flooding that destroys the terrestrial 5G infrastructure, then it can be logistically challenging and slow for them to restore service. An aircraft like ours is ideal because you can launch it and cover a huge area with just a single aircraft. Also in remote areas, terrestrial cell towers are too expensive and it’s the reason why almost 40 per cent of the world’s population live outside of reliable networks. There’s a need for mobile network operators to fulfil the obligation of 100 per cent coverage. So, they are looking into satellite communications or HAPS to extend the networks. HAPS has the big advantage that it really acts like a “cell tower in the sky” that can integrate into existing networks. No special dishes are required and there is an enhanced service quality for a wider user base, which makes HAPS much more promising.

Another use can be for any kind of observation or ISR (intelligence, surveillance and reconnaissance) missions, also for defence and environmental monitoring. Satellites only have revisit times every 1.5 h or so, and our aircraft can provide uninterrupted live coverage of a single location day and night, for long periods. So it really offers something that current systems aren’t able to provide. There are some extremely expensive military UAVs, but our HAPS has a much smaller payload and we’re focusing on the sensor and basically bringing in data at a much lower cost.

In the end, there are many different use cases. Historically, by far the most investment into HAPS came from the telecom sector and we’re keen to see where interest will come from.

What do you value most about the ESA BIC programme?

We really enjoy the community – being here and meeting other startups and the partners has been really helpful for us. We really value having this level of access to the network, receiving exclusive invites to events and meeting investors that we wouldn’t otherwise get introduced to. Having an office at the ESA BIC location is really beneficial as we get to meet other entrepreneurs who are also based in the building, such as Solidflow – we’re planning on selecting the team to provide us with technical support.

Another aspect that has been really helpful is the business support. We’ve been shaping our story for investors and it’s already come a long way since joining in June. And then there’s the incentive funding, which is always beneficial – just having money for materials and make plans to buy a 3D printer and start manufacturing things here in the FabLab. So just having a bit of budget for the tech development is really helpful.

“Be sure to show that you’re not just developing tech for fun but that you actually have a problem that you’re solving – and a market to serve”

Julius Jördens

What was the impetus to apply to ESA BIC when you did?

It all comes down to timing. Spring this year was just a good time, though I do regret not having applied earlier – but I think we just missed the earlier deadline. It is something I would definitely recommend other entrepreneurs to do. Just, be sure to be thorough and take the time with your application – it’s not something you write in two evenings – as you need to give everything a lot of attention. For instance, make sure the space connection is very clearly defined and show that you’re not just developing tech for fun but that you actually have a problem that you’re solving – and a market to serve. I think if you do those things, you’ll be one step closer to success.

What organisations have been key for your journey so far?

Prior to applying to ESA BIC Noordwijk, we took part in the InnovationQuarter programme. This was a 10-week course of intensive market research and it was definitely very helpful. We also just joined as a member of the HAPS Alliance, which we feel is a beneficial network to be part of.

And finally: What’s your favourite thing about space?

Completely unrelated to Wren, I’ve actually always really loved the idea of flying to another planet. Though, in reality, I don’t think it would be nice at all, you know? It’s just full of radiation and it just doesn’t seem nice for a human being to travel so far in space, to colonise Mars or something like that. But I do really love the idea of it.

ABOUT: Wren Aerospace is a Dutch startup developing patented high-altitude pseudo-satellites (HAPS) – unmanned aircraft offering connectivity and sensing capabilities. The Wren HAPS design delivers superior structural integrity, aerodynamic efficiency and stability in harsh stratospheric conditions. Composite materials and hydrogen technologies that were developed for space missions have been leveraged for terrestrial applications, including next-generation communications, surveillance and reconnaissance. The technology offers unmatched latency, bandwidth and image quality. In June 2025, the company joined the 2-year programme of the Dutch business incubation centre of the European Space Agency, ESA BIC Noordwijk. wrenaerospace.com

Validate your business plan and space connection!

Refine and validate your space business idea via the space connection assessment takes place as part of your preparation of applying to ESA BIC. Want to find out more? Meet the team & get your questions answered: